253

elements electronically, the beams also can be focused to yield clearer and less uncertain

results /13/. The sum of delayed signals is given by

( , )

(

)

n

n

V t

t n

τ

ν

τ

∑

=

−

(3)

where

ν

n

(t)

is the signal from the

n

-th transducer and

τ

is the delay time. The result is the

summed signal dependent on delay time

τ

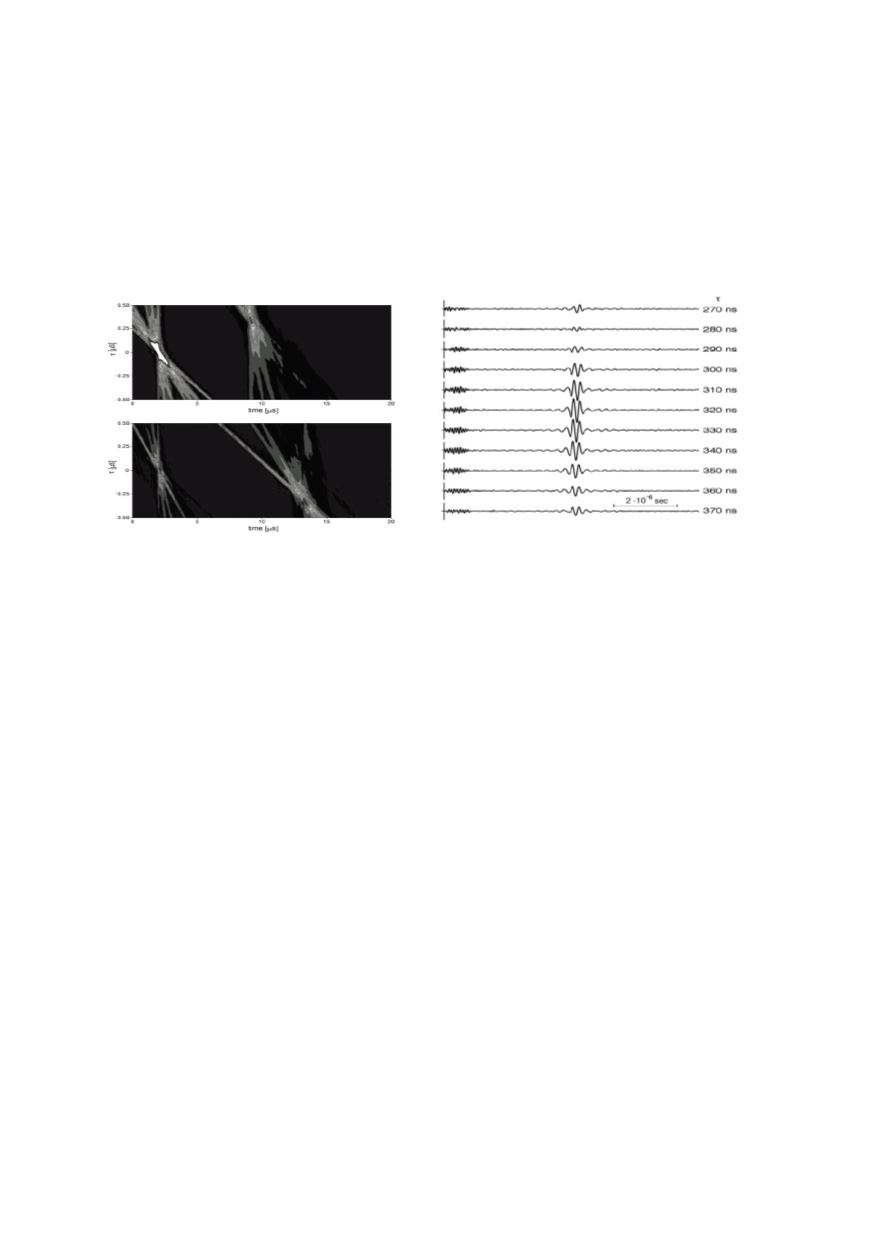

. These summed signals are plotted in Fig. 11,

showing the determination of the delay time between transducers. A maximum amplitude

is obtained when all signals add coherently at

τ

= 330 ns.

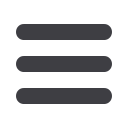

Figure 11: Two illustrations of the phased array technique: the contours of ultrasonic beams at two

locations (left) and sum of delayed signals as a function of the delay time

τ

(right) /13/

Portable phased array ultrasonic instruments offer advantages over conventional

single-element UT, particularly in testing of automated welds in piping. When operating

in scanning mode and using the electronic focusing capabilities of these systems, phased

array ultrasonic systems are significantly faster than single-element systems.

3.4. Acoustic emission

Acoustic emission is a technique to monitor in services or laboratories initiation of

defects and failures in structural materials, applied in structural components (steam pipes

and pressure vessels), and in the investigation of rocks, composite materials, and metals.

Acoustic emissions (AEs) are the stress waves produced by the sudden internal stress

redistribution due to changes in material structure, caused crack initiation and growth,

crack opening and closure, dislocation movement, twinning, and phase transformation as

well as fiber breakage and fiber-matrix debonding in composites, Fig. 12. AE is found to

be an effective way of detecting fatigue and fracture behaviours of materials, too.

AE technique detects the activities inside the materials, through the input of one small

sensor on the material surface in-service or laboratory operation, enabling to monitor

continuously damage development and an early warning of possible failure, including

fatigue damage, but does not produce quantitative results. Since service environments are

generally very noisy, and the AE signals are very weak, signal discrimination and noise

reduction are very difficult, yet extremely important for successful AE application.

Possible sources of AE signals are crack initiation and growth induced by stress

corrosion cracking and hydrogen embrittlement; dissolution of metal; hydrogen gas

evolution; the breakdown of thick surface-oxide films and the fracture or decohesion of