302

Small deviations may occur in situations where the time above A

c1

- or A

c3

-temperature

has some effect on the resulting creep properties, like in cases of particle dissolution.

In the text below the literature example /17/ of Gleeble testing on 9-12% chromium

steels will be shown.

5. GLEEBLE WELDABILITY TESTS ON 9-12% CHROMIUM STEELS

Gleeble simulations representing the shielded metal arc welding (SMAW) process

were applied on specimens taken from pipes of P91 to produce HAZ simulated

microstructures. The cooling time t

8/5

was 21.6 seconds. A special attention was laid on

the evaluation of the soft zone in the HAZ by metallographic investigations using light

microscopy and TEM, hardness tests and constant strain rate tests. The long-time creep

rupture tests were performed to study the effect of the soft zone, which usually

determines the location of creep fracture.

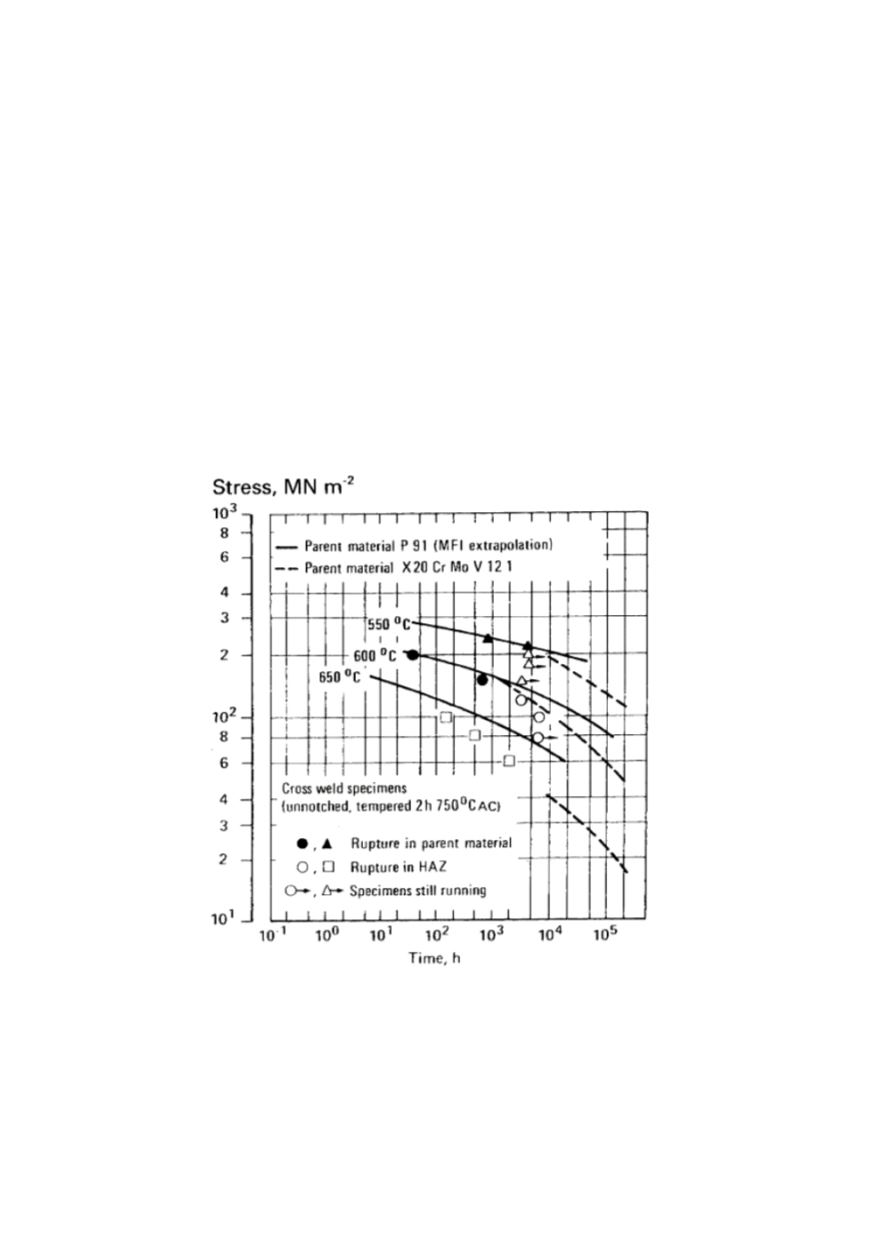

Fig. 4 shows comparison between the creep rupture behaviour of the parent steel P91

and X20CrMoV 12 1 with creep rupture strength of crossweld specimens made of the

same materials. The creep rupture strength of crossweld specimens is significantly lower

at higher temperature than that of parent steel.

Figure 4: Creep rupture strength of parent steel and crossweld specimens of pipe steel P91 and

X20CrMoV 12 1 /17/

5.1. Hardness profile

Hardness profiles across a weld seam of P91 show clearly a tendency to form a soft

zone in the FG HAZ after post weld heat treatment (PWHT), Fig. 5. The hardness in this

particular zone is about 20 HV lower than in the unaffected parent steel. The hardness