211

Segment 9 – adsorbed (entrance part) -

3000x8 /

2000x8

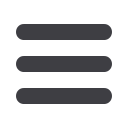

Stress distribution in segment 9 due to thermo mechanical loading is shown in Fig.4.5.

Figure 4.5: Stress due to thermo mechanical loading [kN/cm

2

]

Maximal deformation of segment 9 forthermo mechanical loading is

f

max

= 3.89 cm.

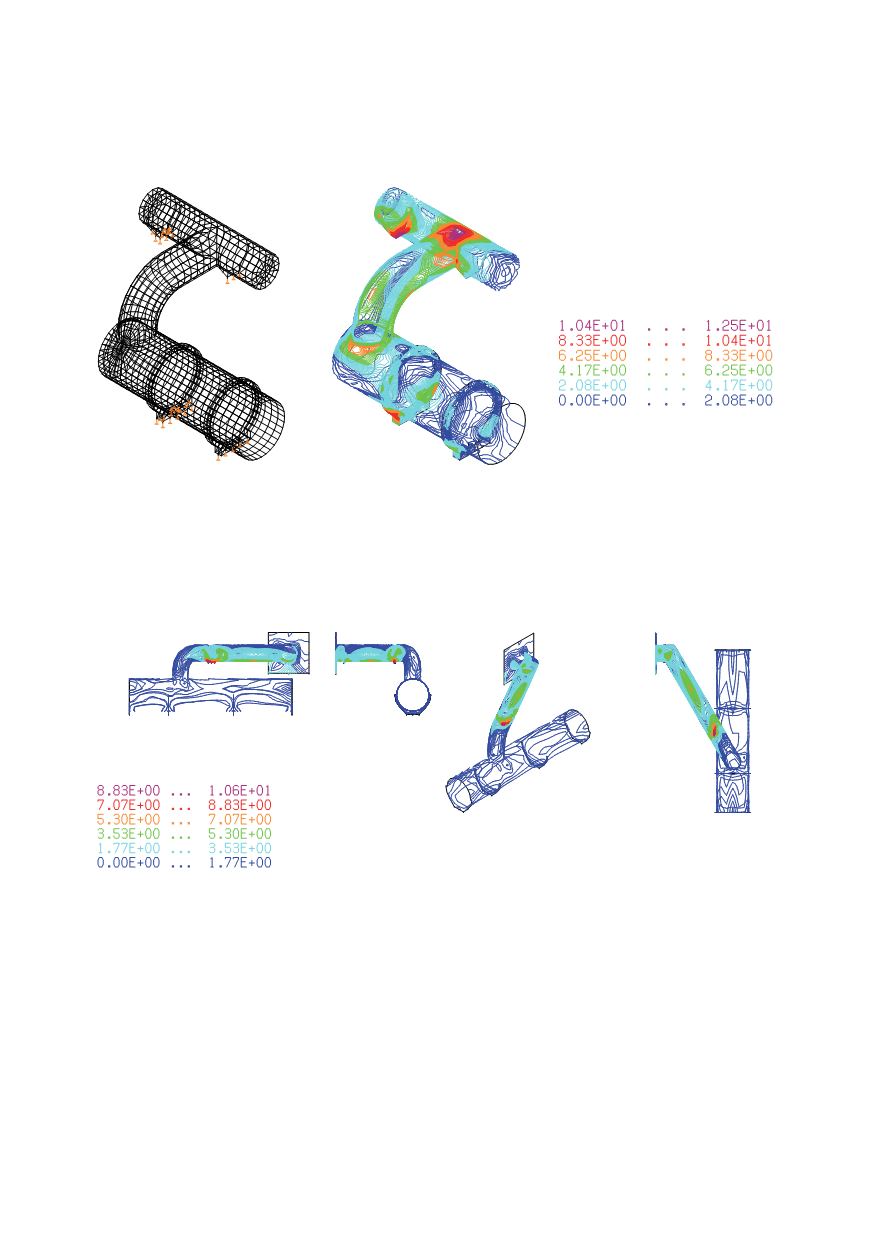

Segment 16 – bypass 2

2000x8 /

4000

[kN/cm

2

]

Figure 4.6: Stress distribution at the temperature 250

o

C for the pipe diameter

4000 mm

Performed analysis of complete gas pipeline in the company RTB BOR allowed to

derive following conclusions:

1.

Analysiswere done for temperatures higher then operating, assuming that the

temperature field in one segment is homogeneous.

2.

Calculated results present maximal stresses at stress concentrations sites; calculated

values of stresses are lower than allowed stress values for corresponding temperature.

The behaviour of gas pipeline as a whole is assessed as satisfactory.

Regular inspection of the construction and supports state has been recommended.

Thermal dilatation of fixed supports should be provided.