197

• performed repairs and replacements,

The application of software of that kind and data base might be the great contribution

to a reliable operation of the equipment. This can be well supported by the possibility of

software to warn on eventual failure.

3.2.Continuous monitoring of component state

In addition to continuous monitoring of process parameters of equipment, like tempe-

rature and pressure, continuous monitoring of component state can be beneficial.

Many different sensors are capable, when involved in corresponding system, to assure

useful information and warnings about equipment component state, like: strain gauges,

piezoelectrictransducers, acoustic emission sensors, electrical magnetic transducers, CCD

cameras, lasersdiodes, and infrared cameras.

4.APPLICATION OF NON-DESTRUCTIVE TESTING IN PRACTICE

Different are causes of structural damage of components.Most important of them

are:overloading, mechanical and thermal fatigue of material,creep, wear, corrosion

(stress, intercrystalline, general), anderosion.

Different methods are applied to detect defects in components during periodical

inspection or overhauls. Some examples from that experience are presented in next text.

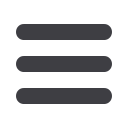

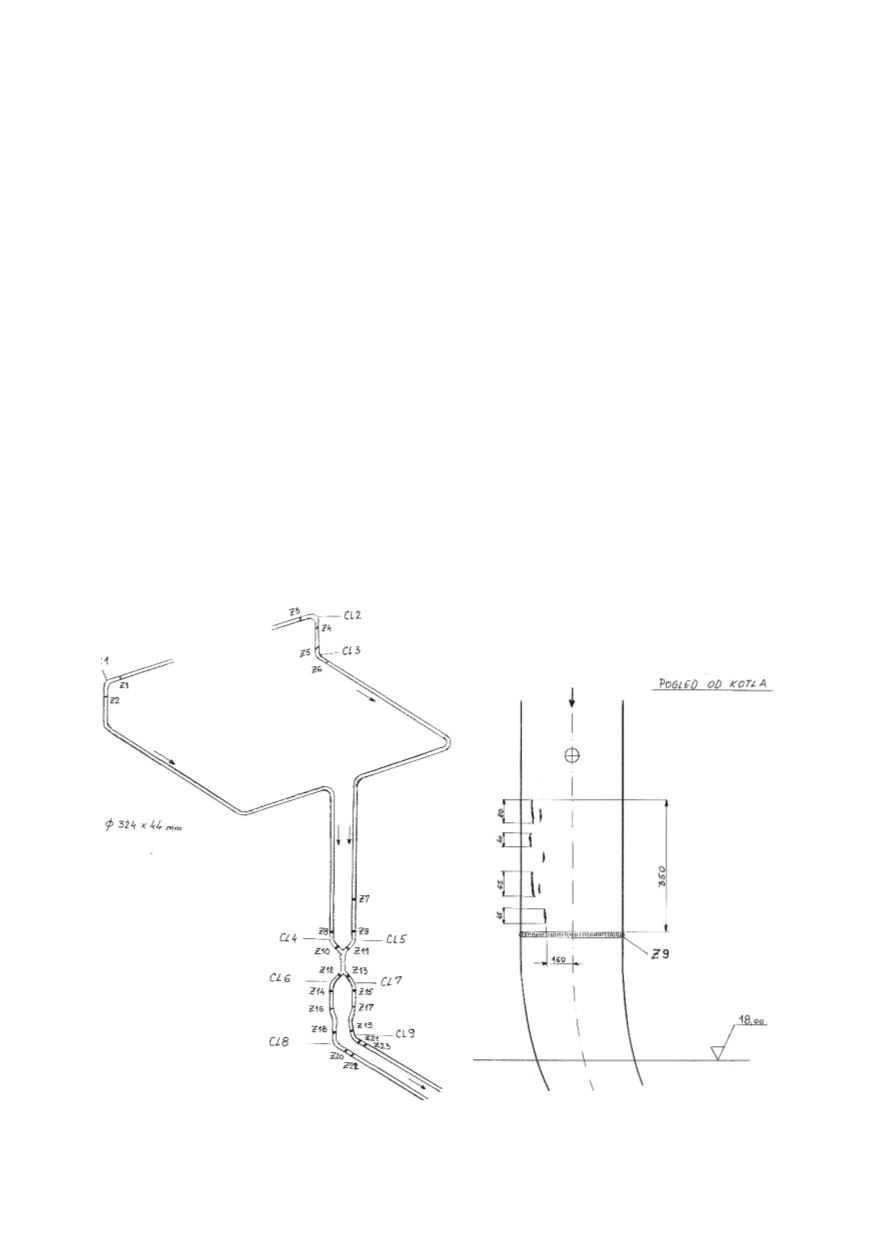

4.1. Steam pipeline in Thermal Power Plant ′′Kakanj′′, unit 7

Steam line in unit 7(230 MW, operating pressure 174.5 barat 545°C), had been

inspected in November 2001(Fig. 1, Fig. 2).

Figure 1: Line of fresh steam – knees and welds

Figure 2: Defects close to welded joint Z9